Dummy

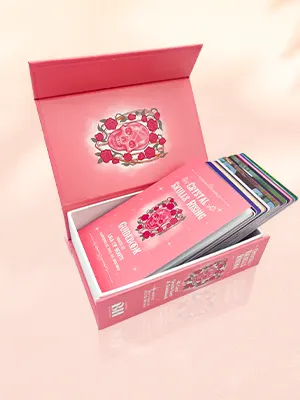

A dummy is also called an unprinted mock-up. It is a made-up blank sample that uses the final printing paper stock and binding method. A dummy helps you check the interior paper, binding method, cover surface lamination, cover paper, book thickness, and book size. It shows you how the final product will look and feel without the printing. The dummy is assembled and bound by hand. This blank sample is an important part of planning a print project. A dummy is produced in conjunction with various proofing methods to give a complete overview before the main print run is commenced. These proofing methods include PDF proofs, digital samples, hard proofs and offset printed samples. Using a dummy in conjunction with the recommended proofing method is the best way to ensure your print job is produced correctly.

When Do You Need a Dummy?

A dummy is ideal to show you exactly how your book will look. It shows the size, thickness, weight and binding style. The exact paper stock, number of pages and binding style are used to produce a dummy. The dummy is an accurate representation of what your printed book will be like. A dummy is a useful tool for both the designer and the customer. Alterations can be made after the production of the dummy before the extra expense is incurred. It is difficult to envisage how a print project will look simply at the artwork stage, as it is only displayed on a monitor. The paperweight chose, for example, may be too heavy or too light. Or the binding style may not suit the number of pages and design. The cover paper stock may not work well with the interior paper stock. It is possible to change these specifications after the production of a dummy but before printing. This will save time in the long term and, of course, money. To check the colour and layout of the whole project a hard proof is ideal as well.

Dummy vs Digital Sample

A dummy is perfect for showing the size, weight, paper stock and binding style of the print project. However, as it is blank, other methods need to be used to check the design aspect of the job. A digital sample is a good starting point to visualize the design and layout of the print project. Although not strictly accurate for colour, a digital sample can be used to check text, image and graphic sizes and positioning. The digital sample is produced on a generic paper stock so it is not a reflection of the paper stock either. It is a good idea to use both a dummy and a digital sample when in the initial stages of the design process. Once these factors are decided, the next stage would be to produce hard proofs or offset printing samples.

Dummy vs Hard Proof

A dummy gives you an accurate representation of how the final print job will look and feel. However, as it is blank, another proofing method is needed to show colour, image quality and position, and text. Hard proof is produced on an Epson inkjet printer that is calibrated to international standards. The method uses a standard inkjet coated paper so it is not suitable for checking the actual stock to be used. A combination of using hard proof and a dummy will provide you with a good idea of how the finished print job will look.

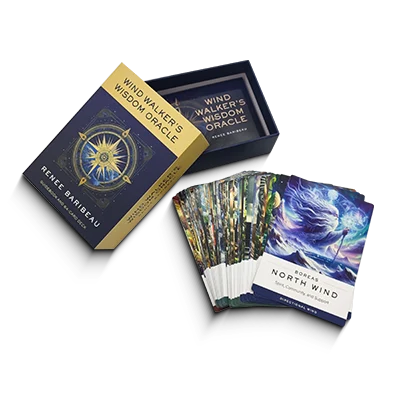

Dummy vs Offset Printing Sample

In order to see how the print job will look at the actual paper stock it is necessary to produce an offset printing sample. This is printed by the same machine, with the same inks and paper that the final job will use. An offset printing sample provides an accurate proof of the final job for the exact colour reproduction on the chosen paper stock. This is particularly useful if an uncoated or tinted paper stock is used. Normally just one section of pages is proofed with the offset printing sample. Together with the folded and trimmed unprinted dummy, you will see exactly how the final printed and folded project will look.

If you produce regular work then the method of proofing will become standardized. For example, the first time you produce a multipage print project on a certain paper stock you may require a dummy, hard proofs and an offset printing sample. If the job is repeated in the future with a different copy but the same specification you may only require PDF or hard copy proofs. This is because you already know how the colours will reproduce and how they will look when trimmed and bound. You are mainly checking for text, image and graphics quality and positioning.

All the proofing methods have a time and cost element to them. Therefore it is important to choose the correct proofing methods for your print project to deliver the perfect result. Contact us at QinPrinting for advice on all aspects of proofing.