Offset Printing

Everything you need to know about the offset printing process

What Is Offset Printing?

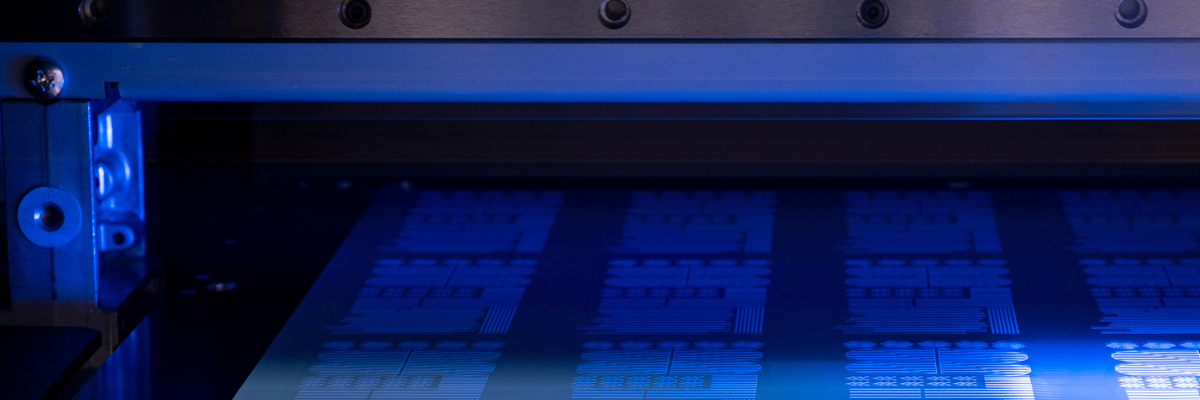

In professional printing, offset printing, which is also known as offset lithography, is a common printing process during which the inked design etched onto a metal plate is printed on a cylinder made of rubber before being transferred to paper or another material. The flexible rubber cylinder’s outstanding malleability enables printing on textured paper, metallic surface paper, leather goods, textile and fabric backing on the paper, and smooth coated or uncoated paper substrates and cardboard.

How Offset Printing Works

Founded on the fact that water and oils are not compatible, offset printing, a variant of lithography, allows for the deposition of oily ink on oil-treated printing sections of the plate while rejecting the ink in nonprinting sections that retain water. The offset plate is often made of zinc, aluminum, or a mixture of metals; its surface is treated to make it permeable, and a substance that responds to light is coated on top. The coating applied on printing sections hardens when exposed to light; on nonprinting regions, the coating gets washed out, leaving wet metal which will not accept ink.

The press used for contemporary offset printing consists primarily of three revolving cylinders: a plate cylinder, onto which a metal plate is attached; a blanket cylinder covered in a rubber sheet; plus an impression cylinder, which pushes the paper against the blanket cylinder. First, a succession of wetting rollers — which put down water in the metal’s engravings — comes into alignment with the plate cylinder. The ink is subsequently repelled by the aqueous regions and accepted by the oily areas as an assortment of inking rollers run over the plate. When the paper rotates round the impression cylinder, the inked design is “offset” from the rubber blanket and reproduced on the paper.

Offset Lithography Printing Processes

With the widespread use of offset printing for various applications, different variations of the process have been developed to better suit each individual application. These variations include:

- Blanket-to-Blanket — this method of printing allows you to print on both sides of the printing surface at the same time. It employs two blanket cylinders and two plate cylinders per colour, printed on modern equipment with four and eight sets, respectively. These sophisticated machines can print in four to eight colours on both sides of the printing surface. This reduces the cost of double-sided printing while also shortening the delivery time.

- Blanket-to-Steel — this technique for printing is precise, but it can only print in a restricted number of colours. With contemporary machines containing 4 sets, 6 sets, or 8 sets, one blanket-to-steel can print one colour. This enables printing in four, six, or eight colours on both sides of the printing surface at the same time.

- Variable-Size Printing — printing this way makes it easier to change the size of the print. It works by using removable sleeves for a quick change. This allows for a cost-effective solution when printing with different repeat lengths instead of a standard length.

- Keyless Offset — Keyless printing uses fresh ink on each revolution of the cylinder. With each revolution, the inking drum removes any residual ink from the cylinder to ensure a consistent print.

- Dry Offset Printing — Dry printing transfers ink to a photopolymer relief plate before transferring the ink to the printing surface, allowing for higher quality prints.

These variations produce extremely high-quality images at a relatively low cost. This makes offset printing a popular choice for any bulk orders. However, smaller orders become more expensive because of the large initial costs of setting up the printing plate, rubber blanket, and inks.

Offset Printing Services

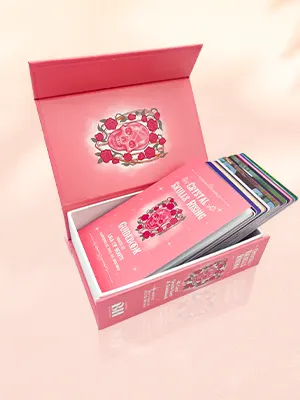

Here at QinPrinting, we offer a comprehensive range of offset printing services. In our facilities based in Shanghai we can undertake almost any print project imaginable. With state-of-the-art technology and machines, highly skilled and dedicated staff, and international scope, we’ve built a global reputation for excellence of which we’re very proud and which we strive to sustain. Our most popular printing products include:

From informational booklets and instruction manuals to luxury high-end catalogues

Custom wall calendars, poster calendars, desk calendars and more, for business marketing, corporate gifts, and retail

Top quality board book printing, self-covered and hardcover, for children or adults

A vast array of customizable packaging solutions with full structural and artistic design support

A one-stop solution for all your board games, game cards, and jigsaw needs, including printing and component sourcing or manufacture

Besides the above core services, we also handle publicity and marketing materials such as brochures, leaflets, and flyers, along with postcards, gift cards, flash cards, posters, magazines, and more.

The Benefits of Offset Printing

Offset printing offers several benefits compared to other forms of printing, such as digital and silkscreen.

- It renders high-quality images and text in either black-and-white, partial or full-colour

- The plates are durable and can produce long runs of thousands of prints with no degradation in quality

- It’s extremely cost-effective when printing large volumes

- The ink flow can be accurately controlled and adjusted during a run without interrupting the printing process

- Because the image and text are transferred via a flexible rubber sheet, accurate printing can be achieved on a range of materials, including fabric, leather, and textured papers

Sheet-Fed Offset Printing vs Web Offset Printing

Sheet-fed offset printing uses a system to feed individual sheets of paper into the offset printer, then prints the pages using the same mechanisms as a standard offset printer. To ensure each page is fed into the printer correctly, this process uses mechanical registration to correlate each page to the other. This makes sure each page is accurately reproduced with the same imagery. Some sheet-fed offset printers also use a perfecting press to allow for printing on both sides of the page at the same time.

Web offset printing uses rolls, or so-called “webs”, of paper supplied into the printer, making it more cost-effective for extremely large order print jobs. This process is typically only used for orders of over ten thousand impressions. They can print large orders at extremely fast rates with some reaching speeds of up to 3,000 feet of paper per minute. Some can cut, perforate, and fold the paper to deliver an end product in the exact form it’s wanted.

There are two classes of web offset printers, coldset and heatset. These two classes of web offset printers differ in the way the ink dries on the page. Coldset printers allow the ink to dry by absorption into the page, while heatset printers use drying lamps or heaters to cure or set the ink onto the page.

Generally, sheet-fed is used in smaller order sizes between 500 impressions and 30,000 impressions. Sheet-fed also produces higher quality prints since they produce on a smaller scale, allowing for more accurate replications. We generally use the web for larger orders of over 30,000 impressions when quality is not as important. The most common use of the web offset process is in the production of newspapers.

Offset Printing vs Digital Printing

Digital printing uses toner sitting directly on top of the paper instead of absorbing into the paper like the ink in offset printing. It uses a combination of Cyan, Magenta, Yellow, and Black dots to produce the image on the paper. This process is typically used for short-run jobs using a large format printer, high volume laser printer, or an inkjet printer.

Offset Printing vs UV Printing

Standard offset printing and UV printing are very similar techniques and can be carried out on the same machines. The key difference is that UV printing deploys specially formulated inks which are sensitive to ultraviolet light. The inks dry almost instantly on exposure to UV light frequencies. One potential advantage of this — other than it being slightly quicker than normal absorption/evaporation or heat drying methods, is that the colours result much crisper and brighter in tone. UV printing is more versatile in that you can print on a wider spectrum of materials such as PVC, metallic paper, soft-touch paper, coloured paper, textured paper, and more. But offset printing is more economical. So, both are good and the choice you make between them depends on the project, the materials, and your budget.

Talk to Us!

Offset and UV printing services are excellent options for custom packaging, board games, books, and more, as they offer a wide range of advantages and can produce high-quality results. Offset printing is cost-effective for larger print runs and offers a great deal of flexibility and choice in the design process and the range of papers, styles, and special finishes, to make your print project really stand out. Over the last 25-plus years, we’ve built up a global reputation for excellence, unbeatable pricing, and fantastic customer service. Get in touch today to discuss your printing needs and we’ll help you draw up the best plan based on your budget.